The ICC Website is changing. As this transition is made, our new format

can be found at www.pesicc.org/ICCWP.

Please send any comments or questions to

mvh@voncorp.com.

Spring 2016 - Presentations

Check this page periodically to learn about the Presentations

scheduled for the Fall meeting.

Please Note: This is a only a listing of the presentations and

UNLESS NOTED, DOES NOT IMPLY THE ORDER IN WHICH THEY WILL BE PRESENTED.

- Opening Session

-

Mini-Expo Vendors

- AP Sensing

- - Static Thermal Ampacity Evaluations are conducted on nearly all

modern day high voltage cable deployments during the cable design phase.

In contrast, Distributed Temperature Sensing is a practical way of

continuously monitoring the cable’s temperature profile in order to

provide real time input for the thermal rating calculations. We will

demonstrate AP Sensing Linear Power Series power cable temperature

monitoring solution along with AP Sensing’s SmartVision solution,

turning data into knowledge and taking the guesswork out of data

analysis. It automatically detects multiple hotspot locations, provides

alarms if critical limits are exceeded, integrates a Real Time Thermal

Rating RTTR Module and creates temperature profiles. All data is stored

in a central database and is fully available for reporting and detailed

analysis. http://www.apsensing.com

- EA Technology USA

- EA technology is world leader in substation condition

monitoring and a pioneer in on-line non-invasive testing of cables,

towers, switchgear, and other substation assets. Our Cable Data

Collector system provides a simple way to perform partial discharge

testing of cables in service with a minimum of training. Expert

analysis of collected data can be done back in the office by EA

Technology or in house by your engineers. Our Cable Sniffer allows easy

location of faulted underground cables without the use of thumper

technology.

- ECI Drilling

International, LLC combines innovation, creativity,

state of the art equipment and tooling, dedicated personnel and

high quality workmanship to be an industry leading driller in

the Horizontal Directional Drilling market. With sister

companies Caldwell Marine, Huxted Tunneling and Northeast

Remsco, all under the JAG Companies umbrella, we offer full

service capabilities for all of your trenchless requirements.

- EJ is the

leader in the design, manufacture and distribution of access solutions

for water, sewer, drainage, telecommunications and utility networks

worldwide. Products include construction castings, gratings, fabricated

metal and composite products. A world class R&D department stands ready

to assist you for custom applications. Learn more at

ejco.com.

-

Elecnor Hawkeye is a respected leader in construction

services. Our Underground Transmission group specializes in the

installation, repair and maintenance of UG high voltage cable,

including XLPE and HPFF. With state-of-the-art equipment, including

cable pull winches up to 80k HPFF, Elecnor Hawkeye can handle any size

job, in any location. The leadership team of the UG group has decades of

experience and understands the importance of working safe and delivering

quality workmanship to its customers. For further information visit

their web site at

www.elecnorhawkeye.com

- G&W Electric Company G&W Electric has been a global leader in providing innovative solutions to the electric power industry since 1905. Our product offerings include cable terminations, cable joints, load and fault interrupting switchgear, automatic circuit reclosers, SCADA and distribution automation products and high current limiting system protection devices. Stop by the mini expo to see our new line of PYTHON™ cable accessories featuring the mechanical shrink installation method. For more information visit

www.gwelec.com.

- HIGHVOLT - HIGHVOLT

produces high voltage AC, DC and Impulse Test Systems and specializes in

Test Equipment for Power Transformers, Cables and all Electrical

Apparatus with the highest levels of customer support and engineering

excellence. Table Top presentations will include Cable Test solutions

for Field and Factory High Voltage testing including details on Mobile

High Voltage Resonant Test systems for HV Cables.

- HV TECHNOLOGIES, Inc.

(HVT), has many years of experience and dedication in serving the

testing equipment needs for the power utility, power apparatus, and

electronic equipment industries. We have been the exclusive BAUR sales

and service partner in the USA since 2008. Come by our booth to see how

our range of VLF, VLF TD, and VLF TD PD testing systems can assist you

with your cable system performance optimization. We also carry a

comprehensive portfolio of Cable Identification, Cable Location, TDR,

Fault Location, and AC and DC Hi Pot instruments. For those interested

in Insulating Fluids Testing we have Dielectric and Dissipation Factor

Instruments that are designed for Lab and Field use. HVT, located in

Manassas, Virginia, is a leading supplier of High Voltage and EMC Test

Equipment and solutions.

-

Kinectrics "Kinectrics’

established industry experts provide clients worldwide with

comprehensive, independent life cycle management solutions in a broad

range of technical disciplines across the energy sector. This includes

engineering and testing services for Transmission and Distribution

Technologies and Generation Plants (Nuclear, Fossil, Hydro and Wind).

Our proven expertise includes on-site commissioning and maintenance

testing for HV and MV underground cables, including established

techniques such as AC Hi-Pot/Withstand, Partial Discharge, VLF Tangent

Delta (Tan δ) and Dielectric Spectroscopy. Kinectrics’ has a fleet of

high-power 260kV Mobile Resonant Test Systems for HV transmission cable

withstand AC Hi-Pot Testing, as well as numerous additional unique

mobile test systems (including advanced diagnostics) for MV generation

plant or distribution system cable aging management/condition

assessment. Kinectrics also offers additional leading-edge capabilities

for HV and MV cables including “one-stop” High Voltage / High Current

lab facilities for qualification testing to international standards and

custom cable R&D programs, forensic services including advanced material

and chemical testing capabilities, and specialized consulting including

advanced modeling/simulation capabilities. Kinectrics’ specialists in

generation, transmission, distribution, and environmental technologies

use innovative science and engineering to help clients improve business.

www.kinectrics.com"

-

LIOS Technologyis

the global leader in the development and supply of state-of-the-art

Distributed Temperature Sensing (DTS) monitoring systems. Building on an

innovative development in the field of fiber optic sensor engineering,

LIOS provides customized solutions in various markets for modern asset

management and global condition monitoring. LIOS EN.SURE DTS monitoring

system and real time thermal rating (RTTR) calculation engine enable

utilities to locate precisely - and before failure - hot spots along a

transmission line in order to dynamically optimize power cable load and

to ensure reliable power supply. With more than 4,000 installations

worldwide, LIOS sets the benchmark in reliability (MTBF > 33-years) and

track record in the Utility transmission & distribution power cable

monitoring industry.

-

Neenah Foundry

is a domestic manufacturer of gray and ductile iron castings for

the Utility Industry. We are pleased to be displaying the

Swiveloc explosion mitigating manhole cover, a solution to the

dangers, liability and costs of a vault explosion or

unauthorized access to underground systems.

www.swiveloc.com

-

Novinium

is the undisputed innovator at the forefront of the utility

infrastructure market. Whether it’s partnering with a utility to

provide manhole solutions for secondary network events, or

combining our rejuvenation technologies with full turnkey

rehabilitation solutions, Novinium is here to help. Novinium’s

featured products include Cablecure®—a revolutionary

injection-fluid technology that provides the longest extension

of cable life available—with a 40-year warranty. In addition,

Novinium introducesPrevent™—a new Manhole Event Prevention

product. Learn more at www.novinium.com.

- Optromix

is a fast-growing manufacturer in the field of fiber optic

sensors and monitoring systems. Optromix provides customized

Distributed Temperature Sensing (DTS) systems, turnkey solutions

for hydro power plants, oil transformers, generators monitoring.

The applications of our DTS systems are as follows: temperature

monitoring of underground transmission and distribution (T&D)

power lines, power plant facilities, coal mines, fire alarm

monitoring (tunnels, factory shops, multistoreyed car parks).

Please find more information at

www.optromix.com.

-

Qingdao Hanhe Cable,

China’s industry leader in HV & EHV cables and accessories. Our

products ranging from Low Voltage to Extra High Voltage covering

industry specific application for Nuclear Power Plant, Energy/Utility,

Mining, Offshore/Submarine, Petro-chemical refineries, High-speed Rail,

Shipboard, and telecommunication. Various samples of EPR/XLPE insulated

overhead, underground, and submarine cable including our 500kV XLPE

cable will be on display.

http://www.hanhe-cable.com/en/index.aspx

- Sumitomo Electric USA Inc.

- J-Power Systems Corporation is the Japanese leading

manufacturing company of extra high voltage power cables and

accessories. We are the leaders of the latest advance power

transmission technology such as HVDC cable up to 500kV, HVAC

underground/submarine cable up to 500kV, and various advanced

challenging installation technology such as XLPE cable installed

in long distance HDD. We will be showing some of the sample

cables and our in-house developed DTS system.

- Taihan Electric USA Ltd.,

is the U.S. subsidiary of Taihan Electric Wire Co., Ltd, the first cable

manufacturer in South Korea and one of the leading cable manufacturers

in the world. We manufacture various cables ranging from Low Voltage to

Extra High Voltage and Accessories. Taihan Electric also provides EHV

engineering solutions and installation services. We will be showcasing

various cable samples including our 500 kV XLPE Underground Cable. For

more information please contact us at 562-946-8500 or visit us at

www.taihan.com/en/

-

Techimp

is a global provider of partial discharge (PD) diagnostic testing and

monitoring equipment and testing services. We are a leading provider of

HV and EHV underground cables commissioning testing services (AC Hi-Pot

and PD) using advanced analysis software providing effective and on the

spot diagnoses. Techimp has also pioneered and is the global leader in

permanent PD monitoring installations for underground HV/EHV cables,

including 500 kV. Additionally, we are the leader in effective online

diagnostics for aged Distribution cables and switchgear. Techimp also

provides PD monitoring of Substation transformers and GIS.

-

Underground Solutions, Inc. Provides the only

fusible PVC conduit and casing systems for trenchless

installation of underground transmission lines. These systems

significantly reduce power ampacity loss compared to steel and

provide additional benefits over other thermoplastics. These

include high tensile strength for longer directional drill

crossings, superior buckling pressure capacity, excellent

thermal resistivity, low coefficient of friction and simplicity

of reconnection with standard PVC conduit. For more

information, stop by our booth to see our full size sample of

the Woodbridge Energy project conduit and casing or visit our

website at

http://undergroundsolutions.com/

- W.A. Chester, L.L.C. is the industry-leading electrical contractor for the installation, maintenance and repair of underground high voltage pipe-type and solid dielectric cable transmission and distribution systems. Founded in the 1930’s, our clients include electric utility companies and independent power producers in the United States and Canada and we are one of three specialty contractors performing this type of work on a national basis. In addition to underground systems, W.A. Chester, L.L.C. has expanded its services to include installation, maintenance and repair of overhead electric distribution cable systems. For more information, please visit our website at

www.wachester.com.

- Walker Engineering

Got HPFF? As a leading provider of pressurizing, circulating and

cooling plants for high-pressure fluid-filled cable networks, Walker is

uniquely qualified to help optimize your HPFF cable system. Through

assessment, testing, restoration, modernization, preservation and

maintenance – Let Walker Engineering be your partner in sustaining the

health of your HPFF cable system. Please visit our website at

www.walker-us.com for more info

on our HPFF products and services including our state-of-the-art

PORTABLE PUMP HOUSE, an invaluable piece of equipment for utilities

during emergencies and outages.

-

Subcommittee A - Cable Construction and Design,

Tuesday April 5, 2016 - 8:00 AM - 12:00 PM

-

Experiences of Combined HV & EHV Cable Qualifications to IEC, AEIC

and the Challenges of adding IEEE 48 or 404 by Caryn M. Riley, Josh

Perkel, Raymond C. Hill, and R. Nigel Hampton NEETRAC, Atlanta, USA,

caryn.riley@neetrac.gatech.edu,

joshua.perkel@neetrac.gatech.edu,

ray.hill@neetrac.gatech.edu,

nigel.hampton@neetrac.gatech.edu

Abstract - Cable Qualifications

combining the elements of AEIC and IEC can be made with sufficient care.

These are always system tests as even if the cable qualification is desired,

suitably robust terminations are required. There are increased risks, but

experience shows that they can be managed. This paper focuses on the issues

associated with taking an existing Cable Qualification (as a system) and

then bringing one or more of the IEEE cable accessory standards into the

AEIC / IEC combination approach for cable system qualification. It first

highlights the similarities and differences associated with the testing

methods, test limits, and number of components/lengths of cable required by

each standard. NEETRAC’s experience with the AEIC / IEC combination

approach from 2005 – 2014 is then reviewed with respect to the overall

failure rate of each component type. Finally, the risks / benefits of

combined qualification programs containing either complex test loops (i.e.

number of components) and / or combined standards requirements is presented.

- High quality carbon black to surpass traditional solution for HV

semicons? Daniele Bonacchi (1), Christine Van Bellingen (1), Denis

Labbé (2) 1 – IMERYS Graphite & Carbon, Bodio, Switzerland,

daniele.bonacchi@imerys.com,

christine.vanbellingen@imerys.com 2 – P&M Cable Consulting LLC, Geneva,

Switzerland, dlabbe@pm-ch.com

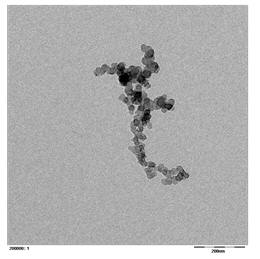

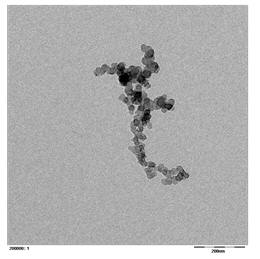

Abstract - The efficiency of the semiconductive layer depends on its

electrical conductivity that is guaranteed by the presence of conductive

carbon black in the semicon formulation. It has been proven that electrical

aging mechanisms are directly linked to semicon protrusion as they locally

increase the electrical field.

Fig. 1: Conductive carbon black TEM picture

As carbon black is an

essential constituent of semicon compound, its quality affects the semicon

performance and hence the final cable lifetime. Any impurities present in

the raw material such as grit (e.g. large amorphous carbon particles

remaining from production) or carbon black agglomerates not to mention ionic

content are detrimental for the final application. While the level of grits

is an intrinsic characteristic of the carbon black used and will remain in

the final compound, the carbon black agglomerates must be dispersed and

distributed by proper processing although only specifically designed carbon

blacks can achieve high level of dispersion. For example low surface area is

linked to large primary particles and is known to favor dispersion thanks to

the better wetting of the aggregates by the molten polymer. Also the high

carbon black structure (e.g. a high degree of branching of the carbon black

aggregates) is known to ease dispersion and distribution thanks to the lower

inter-aggregate interactions and that is why low surface area high structure

carbon black are the only choice for HV and EHV semicon compounds. Although

surface smoothness is the primary requisite for a good semiconductive

compound, other characteristics are essential for a good quality HV cable. A

proper level of volume resistivity at the operating cable temperature and

its stability after thermal cycling is also crucial for good cable

manufacturing. Proper level of conductivity is achieved only at specific

carbon black loading that is in turn dependent mainly on the level of

branching or “structure” of the carbon black aggregates and the intrinsic

carbon black conductivity. In this presentation we will show that an

easy-dispersible, clean carbon black, with higher intrinsic conductivity can

be used at lower loadings than the commonly used carbon black in HV

semicons. By direct comparison we will show the benefits of using lower

amount of the new carbon black, especially the lower viscosity and the

longer scorch time of the compound while keeping excellent surface

smoothness and stable conductivity. Carbon black ionic impurities and

moisture uptake that are transmitted to the final compound and can initiate

electrical treeing will also be discussed in detail.

- Thermo-Mechanical Failure of 345 HPFF

Paper-Insulated Pipe-Type Cable by Carlos Katz & Vitaliy

Yaroslavskiy of Cable Technology Laboratories and Arnold Wong of

Consolidated Edison Co. of NY

A step-by-step investigation and analysis

of the failure of a 345 kV High Pressure Fluid Filled (HPFF) Pipe-Type

cable, 37 years in service will be provided. This cable was insulated with

oil-impregnated cellulose paper. The pipe and three phase cable, in the

area of the failure, were made available. It was discovered that the paper

insulation had been embrittled, apparently, during drying in the cable

manufacturing process. Repetitive snaking of the cable during routine load

cycling caused movement of the paper insulating tapes, resulting in soft

spots, including numerous tape registrations that weakened the cable

insulation structure and ultimately precipitated the cable breakdown. In

spite of the mechanical weakness, electrical tests on the insulating tapes

point to significant retention of original properties.

- Qualification of cables and cables systems

with new EHV accessories for land power transmission – Pierre

Mirebeau – Nexans

-

Subcommittee B - Accessories,

Tuesday April 5, 2016 - 2:00 PM - 5:30 PM

- Suggested Changes to Distribution Joint Standard B22W, IEEE

404 Distribution, Glenn Luzzi – Richards-MFG

Since the first

edition of IEEE 404-1977 there has been a requirement that cable joints

must operate at the same maximum temperature limitations as those of the

cable being joined. However, there has never been a performance test

specified to ensure this criterion is being met. This presentation

suggests several changes for the future “distribution” joint portion of

the standard being developed in B22W. It describes both a performance

test as well as criterion for assessing joint operating temperature

capability. It further proposes a Class 1, 2 or 3 joint based on the

test results.

- IEEE 592 Tests using Current Cable Accessories and

Installation Practices, Thomas Parker - NEETRAC

This

presentation is a summary of two projects performed at NEETRAC to gain a

better understanding of how modern accessories installed using current

installation practices perform under IEEE 592 testing. The results of

these test programs have been presented to ICC Working Group B03W which

is currently responsible for the standard. Topics of interest include:

Impact of jacket restoration on joint test results

Impact of using

15 kVrms

f-f rated accessories on

systems operating at 4.3 kVrms

f-f

-

Subcommittee C - Cable Systems,

Monday April 4, 2016 - 9:15 AM - 12:30 PM

- 9:15 AM - 9:30 AM Opening

- 9:30 AM - 10:00 AM “Mackinaw Straits Submarine Cable

Termination Replacement” by Ken Jauquet, American Transmission

Company, Ron Knapwurst, American Transmission company, John Rector,

Black & Veatch.

The Mackinac 138 kV Submarine cables, installed in

1975, cross the Straits of Mackinac and connect the lower and upper

peninsula of Michigan. On the north side of Lake Michigan, they connect

to a new HVDC Back to Back Converter Station. These cables began

experiencing leaks near at their terminations in the last years. The

leaks persisted and became worse, even after numerous repairs had been

made. The American Transmission Company (ATC) decided the time was right

to replace the terminators and sections of the shore-end cables on each

side of the crossing. The cables were successfully repaired, but not

without some very tense moments. This presentation describes the

unexpected challenges we found and the time critical constraints we had

to work under.

- 10:00 AM - 10:20 AM Break

- 10:20 AM - 10:50 AM “Superconducting cable systems (MV and

HV); update on the 10 kV superconducting project in Germany.”

by Dr. Mark Stemmle, Nexans, Germany

- 10:50 AM - 11:20 AM “Mitigation of a Hot Spot along a 230kV

Cable Circuit Using a Novel Cooling Solution implemented at BC Hydro”

by Dr. S. Cherukupalli (BC Hydro) and Dr. G. Anders (ACO – Anders

Consulting)

This presentation will discuss the results of thermal

studies and some remedial actions examined where a steam pipe and

several distribution circuits crossed a duct bank with 230kV

transmission cables. The presentation will discuss the application of a

novel solution that used a gravitational water cooling system. It will

also describe the implemented system and share some of the measurement

results obtained before and after installation.

- 11:20 AM - 11:50 PM “High Voltage Underground Cable System

Infrastructure in Dense Urban Environments” by Donald N.

Kleyweg, Jr., HBK ENGINEERING, LLC

The project consisted of 6 miles

of underground infrastructure designed for a 345kV XLPE electrical

transmission line in downtown Chicago. The project design process

required a full Subsurface Utility Engineering (SUE) program that

included: the assessment of existing infrastructure including adjacent

building basements, vaulted sidewalks and potentially impacted above and

below grade infrastructure; access to existing below grade utility

structures to perform scans of the extents of the structures and the

routing of existing infrastructure running through them; a geotechnical

investigation program for geo-structural, environmental and thermal

properties of the subsurface soils; advanced design of thermal fills; a

utility vacuum truck test-hole program; a full topographic survey of the

entire alignment and substation tie-ins; a full 3D model of compiled

subsurface conditions for design use in route alignment selection,

manhole locations and existing infrastructure. The project construction

installation process encompassed engineered shored excavations of

varying depth and types including deep trenches, manhole shafts, box

tunnels, drilled soldier pile shafts and directional jack & bore

drilling methods. The installation required the advanced coordination

with: existing utilities for the design of temporary support &

protection systems of their infrastructure that could be affected during

construction activities that would occur over the course of the

installation; coordination with governing DOT agencies, municipalities,

ward alderman and citizens groups.

- 11:50 AM - 12:10 PM Closure

-

Subcommittee D - Generating Station and Industrial

Cables, Wednesday April 6, 2016 - 8:00

AM - 12:00 PM

- 8:00 - 8:15 AM Subcommittee D Business - Art

Maldonado, AM Technology Group - Chair Doug DePriest, TVA - Vice Chair

- 8:15- 9:00 AM IEEE 383 Changes 2003 to 2015,

Robert Konnik - Chief Technology Officer - Marmon Innovation &

Technology Group

Abstract: IEEE 383-2015 was issued in October

2015. Major changes between IEEE 383-2003 and IEEE 383-2015 will be

reviewed. This includes changes in the title, scope, and definitions.

Information on the assumption that type test samples are thermoset will

be discussed. Additional information on type test samples and aging is

discussed. Qualification for normal and mild events including testing

to address wet or submerged environments. Revisions to the section on

flame testing is reviewed as well as how colors may affect

qualification.

Robert Konnik is currently chairman of NPEC SC-2,

chairman IEEE 383, past chair of ICC Sub D, IEEE 323 vice chair and

project lead for IEEE/IEC 60780-323 harmonization as well as member of

many other IEEE committees.

- 9:00 AM - 9:45 AM Wire and Cable Standards - A Canadian

Perspective, Evangeline Cometa - Canadian Standards Association

Abstract - This presentation will provide an overview of the

Canadian regulatory system as it applies to wire and cable. An outline

of various wire and cable types covered by CSA standards with focus on

industrial and commercial applications such as portable power cables,

marine shipboard cables, shielded power cables and others will be given.

The presentation will also provide an insight into the typical mandatory

and optional testing and marking requirements as mandated by Canadian

Codes and CSA standards.

Evangeline Cometa is the Technical Advisor

for Wire and Cable at the CSA Group. She obtained her Bachelor of

Science degree in Chemical Engineering in Manila Philippines in 1977.

She worked at Alcatel Canada Wire (now Nexans ) as a Development

Engineer from 1981 to 1996. She joined AT Plastics from 1996 to 2001

developing tree-retardant XLPE and flame retardant moisture

crosllinkable materials. She has co-authored a number of technical

papers on field failure analysis of transmission and distribution

cables, and has given technical presentations in accelerated aging of

TR-XLPE at past ICC meetings.

- 9:45 AM - 10:15 AM Break

- 10:15 AM - 11:15 AM Fiber Optic Sensing and Condition Monitoring in Nuclear

Plants, Greg McElyea and Douglas S. DePriest

A proposal for

using fiber optic sensing technologies as the underlying technology for

a condition monitoring program. As nuclear plants extend their life

past 40 years and prepare to go beyond 60 it is incumbent upon them to

ensure that their cables are healthy.

- 11:15 AM - 11:45 AM Shield Design of Generation Cables, Douglas S

DePriest

Past shield design used in nuclear plants have limited the

types of tests that can be employed to ensure the quality of the cable

system. There are options available that would alleviate these problems

and updates to the appropriate technical documents should be made to

recommend them.

-

Subcommittee F - Field Testing and Diagnostics,

Monday April 4, 2016 - 2:00 PM - 5:30 PM

- 2:00 PM - 2:10 PM: Welcome, Introduction, Agenda,

SubCommittee F business. Mark Fenger - Chair –Prysmian

Group/Sudhakar Cherukupalli - Vice Chair – BC Hydro

- 2:10 PM - 3:00 PM: “Cable insulation reliability under

repetitive voltage transient supply ”, Proff. Gian-Carlo

Montenari. University of Bologna/TechImp, ITALY

Abstract—Transients

and repetitive transients affect cable insulation life in a waywhich is

not easily predictable at the design stage. Therefore, cable system life

can be shorter than that expected especially when loads controlled by

power electronics are fed, or when HVDC systems are integrated in AC

networks. This paper has the purpose to provide a statistical approach

to estimate the life of a cable insulation system when repetitive

transients, of know probability distribution, are expected to affect

insulation during operation. It is shown, using the Miner law and a

stochastic approach, that life at a given reliability percentage can be

shortened even significantly, depending on transient overvoltage and

repetition rate. Condition monitoring, however, remains the main tool to

keep track of cable heath condition during operation life

- 3:00 PM – 3:35 PM: BREAK

- 3:35 PM – 4:05 PM: “Preliminary on-site classification of

MV cables by using a simple DC insulation tester”, Sverre

Hvidsten, Sintif – NORWAY.

Condition assessment of water treeing in

medium voltage XLPE cable insulations by tan δ measurements is well

established. However, the interpretation of the measurements can be

difficult and even wrong if the cable section has one or more joints

with a low insulation resistance, as the tan δ can be significantly

higher for the joints than for the cable insulation. This presentation

describes a simple method based on using an insulation tester to reveal

if joints with low resistance are present in the cable link.

Measurements have been performed on cable samples with joints taken from

service after more than 20 years due to high tan δ values and partial

discharges located in the cable. The joints were characterized in the

laboratory by time domain dielectric response and dielectric

spectroscopy. It has been shown that both the polarization and

depolarization currents should be used during the assessment to provide

robust evaluation criteria to distinguish the response of a low

resistance joint from heavily water treed cable insulations avoiding

misinterpretation of the cable condition. This method should be used

before applying any other diagnostic equipment for such cables. In

addition, the reproducibility of the measured currents has been

evaluated by performing on-site measurements on different cable sections

with actual joints. It is shown that both the polarization and

depolarization currents remain approximately unchanged, indicating that

robust criteria for cable condition assessment can be established.

Finally, the cause for the high polarization currents (or low

resistivity) of the joints is likely the combined action of water

sorption and thermal ageing of the stress control sleeve.

- 4:05 PM – 4:35 PM “Impact of non-linear grading material on

cable diagnostic – measurement vs. simulations”, Boguslaw

Bochenski, Kinectrics Inc - CANADA

Proper commissioning and

condition assessment of MV and HV cables is primarily based on high

voltage testing. Withstand testing using alternative voltage sources

(i.e. VLF 0.1Hz or 0.01Hz, VLF Cosine-Rectangular, Damped AC) as opposed

to power frequency test sources, can leave critical portions of the

cable system such as field graded terminations and joints less severely

tested, or tested in an entirely non-representative manner. For

example, the electrical field along the insulator surface in

terminations and joints utilizing non-linear field grading materials is

significantly lowered compared to power frequency stress in the critical

‘field limiting region’ around the semi-conductive screen cutback area.

This not only results in a requirement for a differing withstand voltage

requirement for alternative voltage sources compared to power frequency

stresses to achieve the same electrical field in the termination, but

also is one key explanation for differing PD Inception Voltage (PDIV)

and Extinction (EV) voltages, in high field regions in non-linear graded

accessories, when using alternative voltage sources. The presentation

will discuss initial results from steady-state and transient

finite-element based simulations that explain this issue, and proposed

courses of action to mitigate against such issues in commissioning and

diagnostic testing.

- 4:35 PM – 5:05 PM “Progress in Estimating the Value /

Benefit of Diagnostic Testing on Aged Cable Systems ”, Nigel

Hampton

- 5:05 PM – 5:15 PM Closing remarks and adjourn

-

Subcommitee G - Transnational Luncheon

(Registration Required), Tuesday, April 5,

2016, 12:15 - 2:00 PM

- Opening by Frank Petzold

- Distributed Temperature Monitoring as part of a 110kV Grid

Modernization and Reinforcement Project (2012-2018), Uwe

Keppler AP Sensing; Germany

- “Development of ROV installed wet joint on HV submarine cables”,

Geir Clasen Nexans ; Norway

- "Riser Cable Installation for 7MW Floating Wind Turbine in

Fukushima Floating Offshore Wind Farm Demonstration Project",

Hideo Tanaka Viscas ; Japan

- “First 38 km long 110kV XLPE cable project in Poland from

engineering to commissioning”, Andrzej Cichy Tele Fonika ;

Poland

- ” Return from experience with HVDC cable systems with extruded

insulation”, Luigi Colla, Prysmian ; Italy

- “Completition of 345 kV qualification tests from Nan Cable

Guangzhou”, Ivan Jovanovic G&W Electric Company

- “Installation of 300 kV Cable System for KNPC MAB

Refinery expansion project.”, Mike Yu, Hanhe Cable USA

- “Calendar of International Events”, Edward Gulski HV Onsite Solutions ;

Switzerland

- Networking Luncheon (Registration Required),

Monday, April 4, 2016, 12:30 - 2:00 PM

-

Educational Program

- Partial Discharge - The Basics and the Big Questions, Wednesday, April 6, 2016

- 1:00 PM - 5:00 PM

-

- 1:00 – 1:05 PM, Education Session Opening Remarks,

Rachel Mosier, PDC - Chair

- 1:05 - 1:20 PM, PD Fundamentals, Ben Lanz, IMCORP

- What is PD?

- Definition

- Basics of PDIV, PDEV, pC

- How is PD associated with cable system failure?

- Why would there be PD in my cable system?

- Root cause categories

- What are the primary determinates for insulation erosion

associated with PD?

- 1:20 - 1:50 PM, PD Testing in the Factory, Ben

Lanz, IMCORP

- What are the standards for PD QC control in the factory (solid

dielectric)

- Review IEEE, ICEA , VDE, and IEC standards

- Key parameters in common and subtle differences

- How is PD detected in a factory?

- What type of equipment is used and how is the process

performed?

- Types of equipment

- Process

- 1. Sensitivity and calibration

- 2. Overvoltage and duration

- Are there any differences between MV and HV/EHV?

- Sometimes PD tests are performed during type tests, which

include the accessories. Does this change anything?

- 1:55 - 2:55 PM, PD Testing in the Field, Mark

Fenger, Prysmian

- How is PD detected in the field?

- What type of equipment is used? How is the PD picked up?

- How is the process performed?

- How is the background noise overcome?

- Are there any differences between MV and HV/EHV?

- What are the differences between extruded and laminated

systems? What if the system is a mix between the two?

- How can the utility compare the PD level in the factory

with the PD level in the field? (Is there a correlation between mV

and pC?)

- 3:00 - 3:10 PM, Break

- 3:10 - 3:40 PM, PD Testing: Some User Perspectives,

NIgel Hampton, NEETRAC

- 3:45 - 4:05 PM, The Challenge of Performing PD Testing in

the Field: User Perspective through IREQ’s Experience,

Jean-François Drapeau – Hydro Quebec

- 4:10 - 4:55 PM, The Big Questions, Jody Levine,

Hydro One

- How long can a cable system last with PD?

- Can PD testing tell us how aged a cable system is?

- What is the strength and purpose of PD testing?

- What levels of PD matter to me? (Cable, accessories, MV,

HV/EHV, extruded, laminate…)

- If there’s no PD, am I in the clear?

- What type of voltage source should I use? What’s the maximum

voltage I should apply?

- 5:00 PM Close

- Benjamin Lanz received a BSEE degree from the

University of Connecticut in 1999. Since 1997 he has worked for IMCORP

in various R&D, operations, business development, reliability consulting

and asset management consulting capacities and now holds the position of

Director of Applications Engineering. He is a voting member of the IEEE

Power & Energy and Standards Societies. He served as Chairman of the

Insulated Conductors Committee (ICC) workgroups responsible for cable

testing and cable reliability. He has published over a dozen papers on

power system reliability, asset management, and diagnostics and

regularly presents on the topics.

- Mark Fenger is a Dielectrics Engineer with

specialty in condition assessment of medium voltage, high voltage and

extra high voltage cables systems. This includes significant experience

with electrical testing of cables systems in the field and in the

laboratory. Specifically, he has tested more than 3,500 km of HV & EHV

cable systems located in North America, Europe and the Middle East and

has expertise in various test methodologies including AC Withstand

Testing (power frequency and VLF), DC and Damped AC testing combined

with different implementation of field PD measurements. Mr. Fenger's

technical area of expertise is aging of solid dielectrics. He has been

working in the field of insulation diagnostics since 1997 and has

authored more than 40 papers on the subject of insulation diagnostics.

He is an active participant of Cigre and IEEE and is currently convener

of two Cigre working groups (B1.28 and B1.38) on the topic of electrical

field testing of cables and one IEEE work group (F11D). In addition to

having an M. Sc. E. E in Electrical Engineering, he also has an MBA with

a Major in Strategic Marketing and a minor in Management Sciences. He

works for Prysmian.

- Nigel Hampton received a BS in Applied Physics and

Instrumentation from Bath University UK, an MS in Polymer Engineering

from Manchester Polytechnic UK, and a PhD in Solid State Physics from

Bath University UK. He is presently a program manager at the Georgia

Institute of Technology – National Electric Energy Testing Research and

Application Centre (NEETRAC). He is responsible for work in the

reliability area, including condition assessment, forensics, and asset

management. Dr. Hampton has numerous publications with regard to cables

and diagnostics.

- Jean-François Drapeau works as a research scientist

at IREQ, the Hydro-Quebec Research Institute. He received his B.Sc.

degree in Electrical Engineering in 1986, and a M.Sc. degree in 1988,

both from École Polytechnique de Montréal. He joined IREQ in August

1988, where he has lead his career as research scientist for nearly 28

years.

For the last 13 years, he has been working with topics

relating to cable diagnostics. Since 2011, he is the leader of an

important project aimed to gather knowledge and develop a portfolio of

diagnostic methods for condition assessment of the Hydro-Quebec’s

distribution MV underground cable system. Over the course of his

project, he has developed a wide expertise relating to diagnostic

techniques based on dissipation factor and dielectric spectroscopy.

Furthermore, his research team has started to develop expertise on PD

testing back in 2010.

Over the last 5 years, Jean-François has had

the opportunity to familiarize himself and get experience with off-line

PD measurements using a variety of PD diagnostic systems, which include

60 Hz PD, VLF PD, Damped AC PD, and VLF Cosine-rectangular PD.

- Jody Levine is a maintenance engineer at Hydro

One. She received a BSEE and an MSEE, both from the University of

Waterloo. She is an internal consultant to electric utility on

equipment issues, including support for emergency correctives,

developing maintenance plans and work methods, providing input on

equipment specifications and station design. Ms. Levine has wide

experience with high voltage and high current testing, field

diagnostics, failure analysis. Her specialties include grounding, surge

arresters, cables, capacitors, reactors, failure analysis, high voltage

and high current lab testing, assorted HV field tests, particularly

partial discharge testing. She provides guidance for working around arc

flash hazards such as with metalclad switchgear.

0.4 IEEE CEUs will be offered for

this session. You must register in order to receive CEUs. (Please

note, in order to receive these credits towards a Florida PE License,

you MUST provide Thomas Arnold with your FL PE License number prior to the

session.

Return to the Spring 2016 page

IEEE prohibits discrimination, harassment and bullying. For more

information, visit

ieee.org/web/aboutus/whatis/policies/p9-26.html

Privacy & Opting Out of Cookies

Terms & Conditions

IEEE ICC PES & Design is a registered trademark of

The Institute of Electrical and Electronics Engineers, Inc.